Jianbang Machinery daily chemical filling production line xiaobian for you to introduce UHT sterilization machine applicable industry

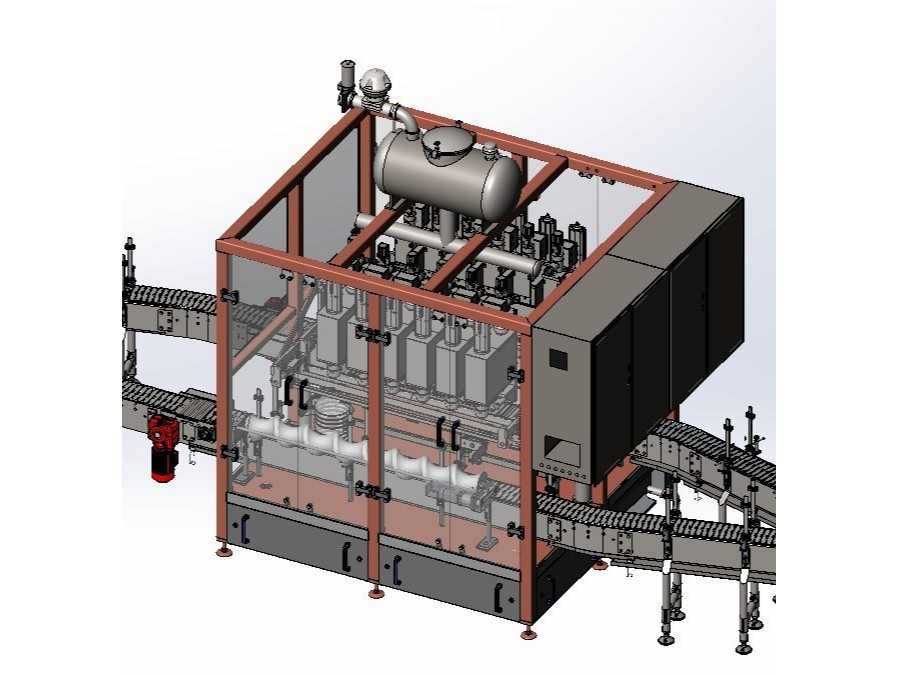

UHTSterilization machine is high temperature instant processing sterilization machine. High temperature instantaneous sterilization temperature is135-140℃, heat preservation4In order to meet the requirements of commercial asepsis, no need to store at room temperature, shelf life up to1-6Months.UHTSterilization machine for industryJianbang machinery xiaobian for you to introduce.